Cast Urethane Services

Open your production possibilities with quality, cosmetically-oriented parts at a reasonable cost

Manufacturing on Demand

RTV Urethane Casting

A cost-effective alternative to injection molding

Looking to create aesthetically pleasing, functional end-use parts in color and texture with repeatable quality output?

This manufacturing process is similar to injection molding, but boasts significantly lower tooling costs.

While injection molding is great for high volume production, urethane casting is ideal for prototyping, bridge production, and production ranging from 10-1,000 units.

How Urethane Casting Works

A master pattern that is either CNC machined or 3D printed with SLA from a CAD file is placed in a mold frame. Liquid silicone is then poured around it to form a mold.

Once mold curing is complete, it is split in half and the pattern is removed – leaving a cavity in the shape of the end part. Resin is then poured into the mold. Once cured, the final part is removed.

This process can be repeated up to 20 times on the same mold before it is considered fully deteriorated, after which a new mold is cast from the master pattern.

Explore Popular Uses for Cast Urethane

- Bridge production

- Functional end-use parts

- Low volume production

- Pilot program for user testing

- Large cosmetic parts

- Sales samples

Technical Specifications

|

|

Cast Urethane

|

|---|---|

|

Lead Times

|

Eight-12 days.

|

|

Standard Accuracy

|

+/- 0.010″, but is extremely feature dependent.

|

|

Typical Order Volume

|

Molds last for 20 parts (dependent on geometry and material used). This process is ideal volume 10-1000 units.

|

|

Finishes

|

Matte, smooth, polished (for clear parts).

|

|

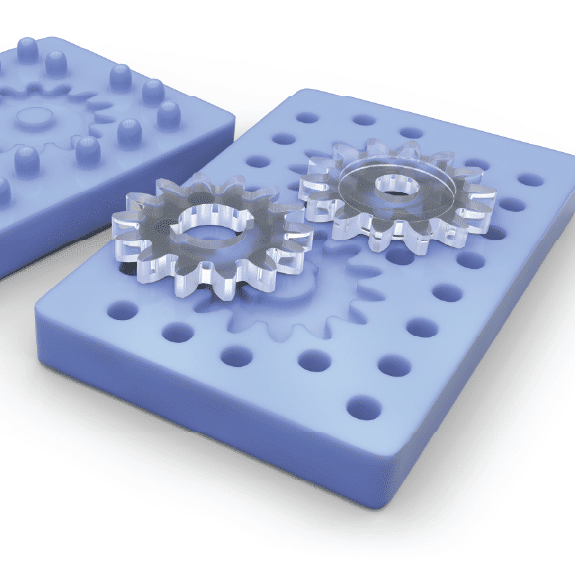

Rigid Material Options

|

ABS-Like, High Temp/PC-like, Clear Acrylic-like, Polypropylene-like, UL94-V0

|

|

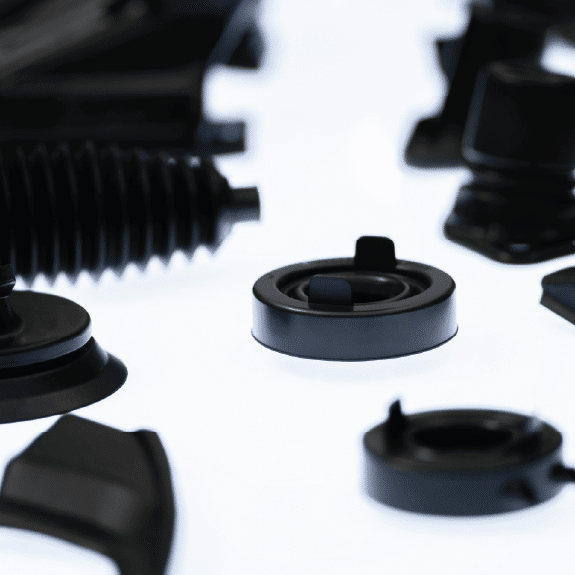

Flexible Material Options

|

Silicone, TPU, Clear TPU

|

Frequently Asked Questions

Wall Thickness

Keep wall thicknesses manageable: 1mm minimum to allow for mold filling.

Releasable Mold

Ensure the mold can be released. No geometries that capture the mold, like narrow mouthed vessels. Many undercuts can be successfully molded.

For color options, we offer tinting (mixing pigment in with the resin), painting and polishing.

Molds yield up to 20 parts per tool (dependent on geometry and material used).