Injection Molding Services

Manufacturing on Demand

Tooling and Injection Molding

Meet your production needs with injection molding

If you’re looking for high volume production, injection molding may be the manufacturing process for you.

This traditional method creates high quality end-use parts with versatile materials – all in a repeatable process.

Whether you need low-volume prototype tools or hardened steel production tools, or need additional add-ons for challenging geometries, our knowledgeable tooling engineers can help.

How Injection Molding Works

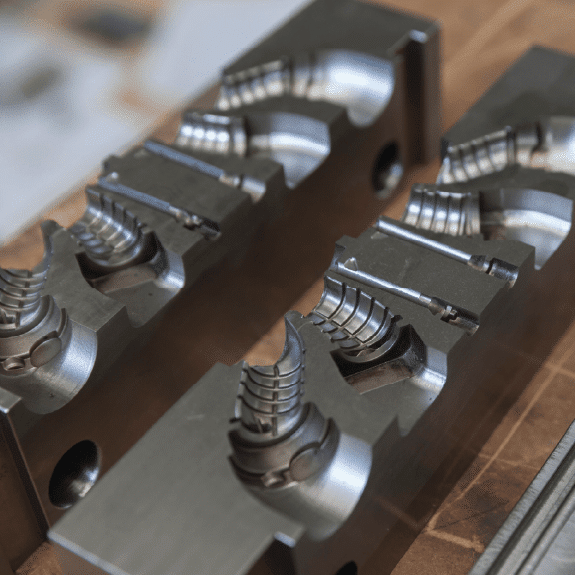

It all begins with a CNC machined tool or mold.

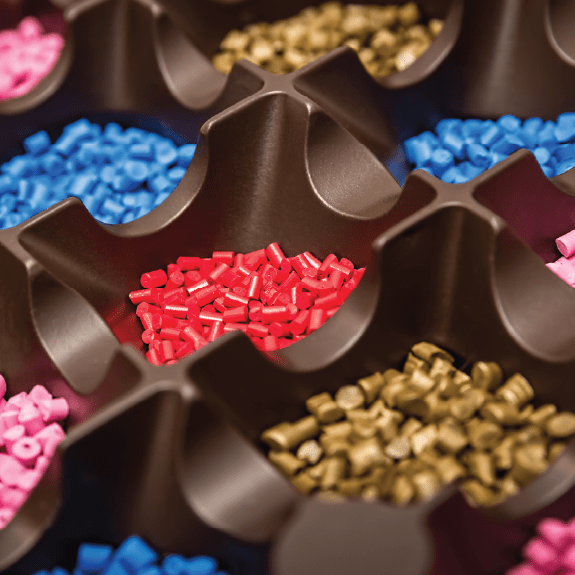

Our experts manufacture a mold from your CAD part and drawing files that leaves a cavity where the part will be injected. The injection mold machine then injects heated material pellets into your mold at a high speed and pressure.

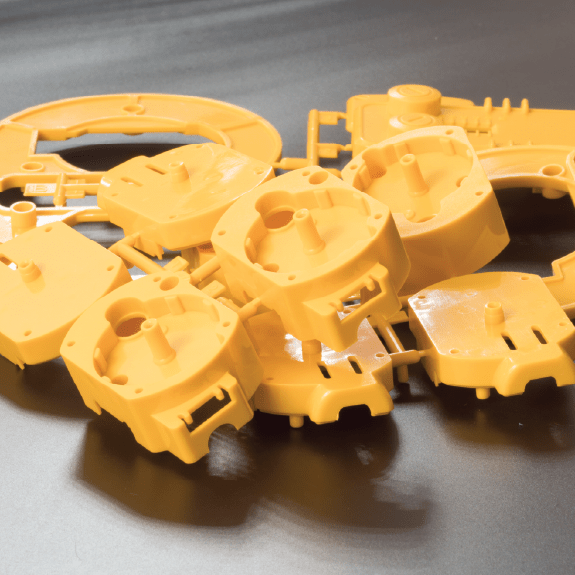

The mold separates, leaving an injection-molded part. This process can be repeated for thousands of cycles.

Explore Popular Uses for Injection Molding

- High volume production

- Medical

- Consumer goods and electronics

- Automotive

- Aerospace

Technical Specifications

|

|

Injection Molding

|

|---|---|

|

Lead Times

|

Typically two to four weeks, but is dependent on your project.

|

|

Standard Accuracy

|

Tolerances of +/-0.005 in, but critical or small features can be held much tighter.

|

|

Typical Order Volume

|

0-1,000,000 units.

|

|

Rigid Material Options

|

ABS, PC/ABS, Acetal, HDPE, LDPE, Nylon, PEEK, PEI, PETG, Polypropylene, Glass Filled Nylon

|

|

Flexible Material Options

|

Silicone, TPU

|

Frequently Asked Questions

You can specify a wide variety of surface finishes including SPI and Mold Tech standards.

You can also provide Pantone or RAL color codes to tint or paint parts.

We do not have a minimum quantity.